GLI COMPANY NEWS

2015

GLI has licensed MASTA by Smart Manufacturing Technology which helps increase efficiency, and lower costs in transmission and drivetrain system development and manufacture for parallel axis gear systems.

MASTA is a complete suite of CAE software for the simulation & analysis of advanced transmission systems from concept through to manufacture. Comprising a large number of inter-operable modules, MASTA can be applied to all industries that use gear-shaft-bearing systems.

Key Focus Areas

• Gear System Analysis

• Component Rating

• Optimization

• Manufacturing Simulation |

|

2014

|

GLI President Brian Schultz joins the American Gear Manufacturing Assocation's Board of Directors.

|

Kellenberger Kel-Vista UR 175/1000

GLI increases cyclindrical grind capabilities

|

This high precision cylindrical grinder is equiped with a multi-wheel head allowing for external, internal and face grinding in the same setup. |

|

October 2012

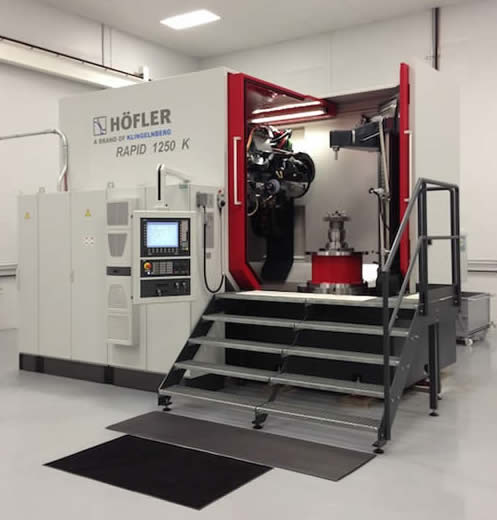

GLI has established a dedicated grinding hall to support the installation of a Höfler Rapid II 1250 K Profile gear grinder. This grinding hall is fully climate controlled and equipped with a 5 Ton overhead crane. The hall will house addition grinding equipment planned for future installation.

Höfler Rapid II 1250 K Profile Gear Grinder Specifications

- Latest in profile gear and pinion grinding technology

- Gear accuracy to DIN standard 3960/3962 Grade 3, AGMA 2000 Class 14

- Gear diameter of 1250 mm (50") and face width up to 1000 mm (40")

- Onboard inspection system

- Special spindle configuration for small grinding wheels allowing for grinding restricted root sweep outs

- Supports flank modifications including bias free or controlled bias

- Grind from solid

- Prepared for internal grinding attachment |

|

|

|

September 2012

GLI increases gear cutting capacity with the addition of a LC502 CNC Hobbing Machine.

LC502 Specifications

- Crowned, Tapered, Spur, Helical and Worm Wheel Gears

- Workpiece Diameter of 500 mm

- Facewidth up to 400 mm

- Workpiece Length up to 725 mm

- Diametral Pitch (coarsest) of 10 module

- Hob Speed Range of 45-720 rpm

- Single Index Milling |

|

April 2011

GLI establishes dedicated gear metrology lab including a Klingelnberg P100 Analytic Gear Measuring Machine.

P100 Specifications

- Gear Measurement to VDI / VDE 2612 - 2613 - Class I

- Evaluation according to AGMA 2000, AGMA 2015

DIN3960/3962, ANSI

B92.1, ISO 1328 and free tolerances

- Capable of inspecting gears, pinions and shafts up to

1000 mm in length and diameter

- Integrated gear tooth roughness inspection

- Shaft inspection and Gear Hob Tool inspection

|

|

April 2010

GLI's QMS is certified to AS9100D.

AS9100D

|

GLI's Quality Management System has been assessed by NSF-ISR and is in conformance to the AS9100D standard.

This certification is another example of our commitment to providing the highest quality products possible to our valued customers.

Click Here to view our Certificate of Registration |

December 2009

GLI increases gear cutting capacity with the addition of a LC255 CNC Hobbing Machine.

LC255 Specifications

- Crowned, Tapered, Spur, Helical and Worm Wheel Gears

- Workpiece Diameter of 255 mm

- Facewidth up to 250 mm

- Workpiece Length up to 725 mm

- Diametral Pitch (coarsest) of 6 module

- Hob Speed Range of 60-600 rpm |

|

June 2009

GLI expands high precision offerings for the defense industry.

GLI now has the capability to provide cross tooth shaft flanges meeting ISO Standards 8667 and 12667. These high precision components are used in heavy duty truck suspension systems.

GLI has designed and implemented a high production manufacturing process that utilizes our high precision Makino machining centers and custom designed cutting tools to meet the tight tolerances required for these components.

ISO 8667:1992

Commercial vehicles and buses --

Cross-tooth gearbox flanges, type T

|

ISO 12667:1993

Commercial vehicles and buses --

Cross-tooth propeller shaft flanges, type T |

July 2008

Large diameter gear cell released to production

GLI has released a large diameter gear manufacturing cell to production. This manufacturing cell is capable of turning, hobbing, automatic deburring, milling and drilling of crowned spur and helical gears up to 685 mm (27 inches) in diameter.

The organization of this cell allows for efficient processing of large gears by performing multiple operations simultaneously by a single operator. This improves quality and reduces lead times for large gears. |

660 mm Diameter

Crowned Ring Gear |

February 2008

GLI has added PC-DMIS Gear inspection software.

PC-DMIS Gear

|

PC-DMIS Gear automates the measurement of both spur and helical gears and provides a flexible set of built-in report formats including Pitch/Runout, Profile/Helix, Tip Circle and Root Circle.

PC-DMIS Gear conforms to multiple international standards including AGMA 2000-A88, DIN 3962, JIS B 1702 and ISO 1328.

PC-DMIS Gear uses our high precision Ziess DB900 Coordinate Measuring Machine for inspection. |

January 2008

GLI expands our high speed milling capacity with the addition of a Makino A61 HMC.

A61 Specifications

| Pallet: |

19.7" |

| X: |

28.7" |

| Y: |

25.6" |

| Z: |

28.7" |

| Spindle RPM: |

12,000 |

| Rapid Traverse: |

1,969 in/min |

| Cutting Feedrate: |

1,969 in/min |

| Maximum Workpiece: |

ø31.5" x 39.4" |

| ATC Capacity: |

134 |

| Tool to Tool: |

0.9 Seconds |

| Chip to Chip: |

2.5 Seconds |

|

|

December 2007

GLI increased turning capability and capacity with a DaeWoo Puma V550-2SP twin spindle VTL. This new addition allows GLI to turn diameters over 28 inches.

Puma V550-2SP Specifications

|

| Chuck Size |

25" / 24" |

| Max Swing Diameter |

31.5" |

| Max Turning Diameter |

28.7" |

| X Axis Stroke: |

15.4" |

| Z Axis Stroke: |

31.0" |

| Spindle RPM: |

20 - 2,000 |

| Spindle Motor: |

HP-30 min: 50 |

| Cutting Feedrate: |

1,969 in/min |

| Number of Tools |

10 + 10 |

|

February 2007

GLI has increased our turning and mill/drill capabilities and capacity with the addition of Fuji TN41 turning centers and Fuji HM34 milling and drilling centers.

TN41 Specifications

| Spindle dia.(mm) |

120 |

| Spindle speed(min-1) |

2220 |

| Slide stroke(mm) |

X-axis |

265 |

| Z-axis |

465 |

| Tooling |

12-position turret |

| CNC Control |

Fanuc 21i |

|

|

HM34 Specifications

|

| Recommended work size(mm) |

200 diameter ×120 |

| Spindle dia.(mm) |

100 |

| Spindle speed(min-1) |

5000 |

| Slide stroke

(mm) |

X-axis |

275 |

| Z-axis |

355 |

| Y-axis |

230 |

| Tooling |

10-position turret |

| NC device |

FANUC 21iMB |

|

July 2006

GLI will be more efficient with addition of a Brother CNC high speed drilling and tapping center.

TC-S2A Specifications

| Spindle speed(min-1) |

10,000 |

| Rapid Feed Rate |

Z:50m/min

X, Y: 36 m/min |

| Work Area (mm) |

X-axis |

480 |

| Y-axis |

360 |

| Z-axis |

270 |

| Tooling |

14 tool capacity |

| Tool Change Time |

1.8 sec |

|

|

June 2006

GLI has improved our gear hobbing capabilities with a Gleason Phoenix 125GH CNC hobbing machine. This machine is equipped with auto load capabilities.

- Crowned, Tapered, Spur, Helical and Worm Wheel Gears up to AGMA class 11.

- Work piece Diameter of 125 mm

- Diametral Pitch (coarsest) of 3.2 module

- Hob Speed Range of 150-1500 rpm

- Work spindle Speed Range of 5-250 rpm

- Fanuc CNC Control

June 2006

GLI added a Zeiss CMM with Open DMIS software for complex inspection.

Zeiss DB900 CMM

|

Measuring Strokes:

(X) Bridge Axis 1200 mm (46”)

(Y) Bed Axis 1500 mm (58”)

(Z) Vertical Axis 900 mm (36”)

Measuring accuracy in compliance to CMMA specification

U3 = 6 + L/250

Linear scales of 1 micron resolution

|

May 2006

GLI upgraded our CAM and CAD systems to Solidworks 2007 and FeatureCAM 2007.

March 2006

GLI improved our high precision milling capabilities with a Makino S56 vertical machining center.

S56 Specifications

|

| Table Size: |

39.4" x 19.7" |

| X: |

35.4" |

| Y: |

19.7" |

| Z: |

17.7" |

| Spindle RPM: |

12,000 |

| Rapid Traverse: |

1,574 in/min |

| Cutting Feedrate: |

1,574 in/min |

| Maximum Workpiece: |

39.4"x19.7"x17.7" |

| ATC Capacity: |

20 |

|

January 2006

GLI has added 3 dual spindle high production turning centers.

The Fuji ANW-41T can simultaneously machine the front and back of a workpiece with turning, facing, threading, grooving and boring in a single set-up, unmanned.

- Built-in FUJI L291B/J swing arm robot

- Dual spindles for front and back machining

- Hardened and ground box way construction

- Auxiliary loader for faster load/unload

- Spindle Diameter 4.72”

- Spindle Speed 3000 RPM

- Spindle Motor 30 HP

- Slide Stroke: X Axis 10.43”

- Slide Stroke: Z Axis 17.91”

- Turret: 12-Position

|

|

|